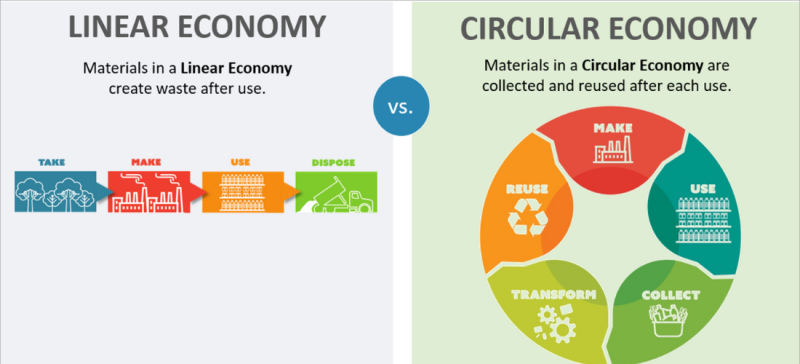

The circular economy is a production and consumption model that involves sharing, renting, reusing, repairing, renewing and recycling existing materials and products as many times as possible to create added value. In this way, the life cycle of products is extended.

It means reducing waste to a minimum. When a product reaches the end of its life, its materials are kept within the economy whenever possible. They can be used again and again, thus creating additional value.

According to the Ellen MacArthur Foundation, the circular economy is based on three principles:

- Designing out waste and pollution

- Keeping products and materials in use

- Regenerating natural systems

A circular economy model has the intention of designing out waste. In fact, a circular economy is based on the idea that there is no such thing as waste. In order to achieve this, products are designed to last (good quality materials are used) and optimized for a cycle of disassembly and reuse that will make it easier to handle and transform or renew them.

What does that mean for entrepreneurs? You will need to get familiar with the entire life cycle of your product or service: Where do you source your materials? How can you keep resources in circulation? How can you recover or regenerate products when they are no longer needed?

By designing out waste and pollution, the circular economy benefits people and the environment. But it creates business opportunities, too. Entrepreneurs can minimize the economic losses in their production process and face fewer risks from the decreasing supply of natural resources.

A Circular Flow of Resources

What exactly happens to resources in the circular economy?

In the linear economy, after a product has broken or served its purpose, it is thrown away. We can identify a clear beginning and end to the product’s life cycle.

In the circular economy, there is no beginning or end to a product’s life. Instead, when materials are no longer needed, they enter a circular flow where they are reused, repaired, recycled, remanufactured, or returned to the biosphere.

Here are some examples of how products find new life in the circular economy:

- Reuse: A product is reused by the customer or offered as a service. Example: A car sharing service allows many people to rent the same vehicle.

- Repair: A product is upgraded or maintained to extend its life. Example: A clothing company repairs worn jackets and sells them to customers.

- Recycle: A material such as glass, paper, or plastic is collected and processed so it can be used again. Example: A recycling center melts plastic soda bottles into pellets that are used to produce new bottles.

- Remanufacture: A manufacturer breaks down old products into parts that can be used to produce new products. Example: An electronics company collects old tablets and disassembles them into components, which are remanufactured into new tablets.

- Return to the biosphere: A product returns nutrients to the earth. Example: Coffee beans are packaged in a biodegradable bag.

Circular Design Strategies

There are steps you can take to move your project toward the circular economy.

In their Circular Design Guide, the design firm IDEO and the Ellen MacArthur Foundation developed a list of strategies to make products, services, and business models more circular.

- Make your product a service: Rent or lease access to your solution, instead of selling it as a product. This approach can also make your products more affordable to low-income customers who may not be able to pay an upfront cost.

- Extend your product’s life: Extend the life of your product by designing for durability or repairing and remanufacturing. You can offer a maintenance service or make it easier for the customer to repair the product themselves.

- Choose your inputs: Choose inputs that are recyclable or biodegradable, or use waste materials to design your product. Remember that some communities may lack the infrastructure for recycling or composting, so be sure to research your system.

- Close the loop: Collect your waste materials for recycling or reusing. When a company recovers its own discarded products, it is sometimes called a “take-back program.”

- Think locally: Source your materials locally and move production closer to your customer. This approach will reduce the waste associated with transportation.

CASE: Managing Electronic Waste

No matter where you live, the electronic waste (or “e-waste”) from laptops, cell phones, microwaves, and televisions is difficult to collect and process. But the problem is particularly devastating in developing countries that lack the infrastructure for managing waste.

Electronics are built to have short lifespans, often lasting no more than a few years. In 2016, only 20 percent of the world’s electronic waste was found to be recycled appropriately. The remainder was likely dumped or recycled under unsafe and unsustainable circumstances.

In informal recycling operations, adults and children are paid low wages to extract valuable metals from electronics, exposing themselves to harmful substances like lead and mercury. The rest of the waste is dumped and burned, releasing toxic fumes and contaminating soil and water. (Agbogbloshie, Ghana, is among the best known of these electronic waste sites.)

How can we minimize this damage to health and the environment, while recognizing the economic pressure that leads people to dump and burn electronics? The value of raw materials in e-waste is estimated to total $65 billion. Some entrepreneurs are helping informal recyclers claim a piece of this value by connecting them with formal recycling or refurbishment facilities.

Electronics manufacturers play a role in the challenge, as well. Companies can design products that are longer lasting and easier to disassemble. Companies can also strengthen their “take-back policies,” and reclaim unwanted products to ensure the waste is properly reused or recycled.

Finally, enterprises that provide electronics should make plans for their product’s end of life. Worldreader donates e-readers to schools and libraries in Africa. The nonprofit partnered with an e-waste management company in Accra, Ghana, to process the e-readers when they can no longer be used.